- Vorführgeräte/B-Ware

- Werkzeuge & Zubehör

- Batterien, Knopfzellen

- Chemikalien

- Ersatzteile- & Reparaturservice

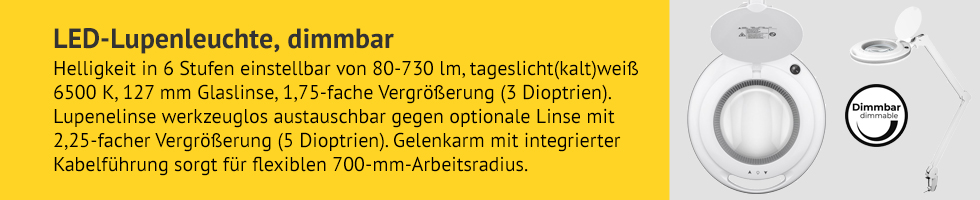

- Lupen, Lampen, Leuchten

- Löten, Schweißen, Kleben

- Metallbearbeitung

- Modellbau-Werkzeuge

- Poliermittel

- Reinigen

- Schmelzen, Gießen, Galvanik

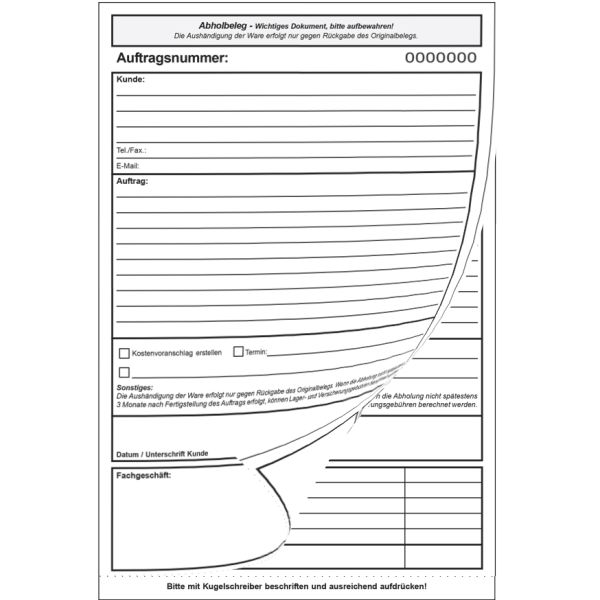

- Werkstatt & Service

- Wiegen, Messen, Prüfen

- Zangen, Pinzetten, Schneider

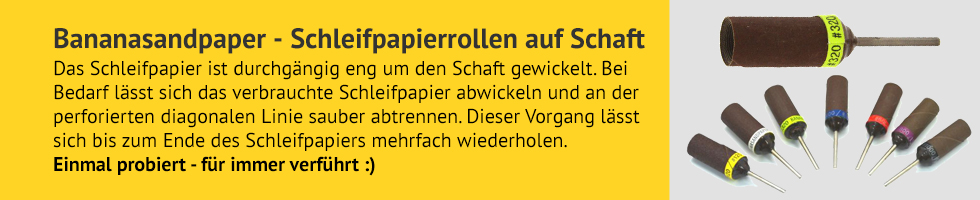

- Zerspanungstechnik

- Schmuckteile & Zubehör

- Anhänger, Ringe

- Aufreihmaterial

- Anleitungsheft

- Aufbewahrung

- Crimpzange

- Elastic Cord

- HP-Seide 1 Nadel/2 Meter

- HP-Seide 2 Nadeln/2 Meter

- Illusion Cord

- Jewelry Wire + Stahlseide

- Lederbänder

- Naturseide 1 Nadel/2 Meter

- Naturseide 2 Nadeln/2 Meter

- Naturseide 2 Nadeln/4 Meter

- Nylon-Satinkordel

- Nylonseide 1 Nadel/2 Meter

- Perlknüpfpinzette

- Perlnadeln

- Perlseideschere

- Polyesterfaden

- Rollenseide

- Spiralen

- Verbindungsseide

- Beads & Charms

- Blech, Draht & Halbfabrikate

- Furnituren, Schmuckteile

- Bajonettschlösser

- Biegeringe, Ösen, Platinen

- Chatons, Zargenfassungen

- Federbügel

- Federringe

- Gravurplatten und Scheiben

- Herrenschmuck

- Kapseln, Endteile

- Karabiner

- Ketten, Armbänder

- Armbänder

- Brillenketten

- Fußkettchen

- Halsketten (Colliers)

- Identitätsbänder

- Meterware

- Ankerketten, diamantiert

- Ankerketten, normal

- Ankerketten, weit

- Doppelankerketten

- Erbsketten

- Figaroketten

- Fuchsschwanzketten

- Haferkornketten

- Kaffeebohnenkette

- Kautschuk

- Kesselketten

- Kugelketten

- Lederketten

- Olivkette

- Panzerketten, flach

- Panzerketten, rund

- Panzerketten, S-Form

- Phantasieketten

- Saiten

- Schlangenketten

- Schlauchketten

- Venezianerketten

- Zopfketten

- Sicherheitskettchen

- Steinketten

- Uhrketten

- Verlängerungskettchen

- Kugeln

- Münzfassungen

- Nadeln, Haken, Scharniere

- Ohrringe, Brisuren, Creolen

- Perldraht, Galerien

- Ring- & Zungenschienen

- Schlaufen, Tulpen

- Schlüsselringe, Zubehör

- Schlösschen, Zubehör

- Achtersicherung

- Armbandschließen

- Bauteile

- Collierschlösschen

- Elfenbein & Bernstein

- Endkappen

- Kastenschlösschen

- Kettenverkürzer

- Knebelschlösschen

- Kugelschlösschen

- Magnetschließen

- mit Perlen & Steine

- S-Haken

- Schließen für mehrreihige Ketten

- Schließen unecht

- Schnepper

- Steckverschluss

- Stäbchen & Stege

- Verschiedene Formen

- Wechselmechanik

- Seitenteile, Aufsätze, Einlagen

- Stiftösen

- Zwischenteile

- Fußball-/Fan-Artikel

- Lot & Gussmaterial

- Modeschmuck

- Piercing

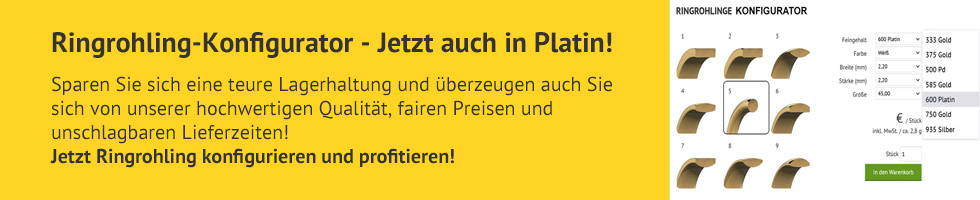

- Ringrohling-Konfigurator

- Uhrenarmbänder

- Schmucksteine & Perlen

- Perlen

- Schmucksteine

- Achate & Quarze

- Amethyst

- Anhänger

- Aquamarin

- Bergkristall

- Bernstein

- Blaufluss (Glassynthese)

- Brillanten

- Chalcedon

- Chrysopras

- Donuts

- Goldfluss (Glassynthese)

- Granat

- Grandeln

- Iolith

- Jade

- Jaspis

- Ketten, Armbänder

- Korallen

- Kugeln

- Labradorith

- Lava

- Lemonquarz

- Luxcera

- MarGems-Steinelager

- Markasit

- Maschinenschliff

- Masterset

- Moissanit

- Mondsteine

- Murano-Glas

- Muschel-Cameen

- Nanogems/Alpinit (Glassynthese)

- Opale

- Pampeln

- Peridot

- Pre-Setting (gefasste Steine)

- Rauchquarz

- Rhodolith

- Rubin

- Saphir

- Simili (Glasstein)

- Smaragd

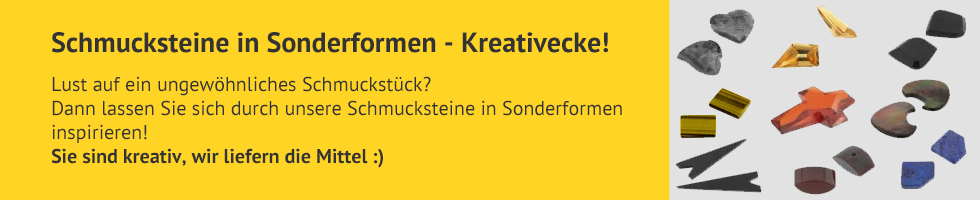

- Sonderformen

- Sondersteine

- Sortimente

- Spinell, schwarz

- Stränge

- Synth. Korunde und Spinelle

- Soudee

- Synth. Korund Alexandrit

- Synth. Korund Damburit

- Synth. Korund Kunzit

- Synth. Korund Padparadscha

- Synth. Korund Rose de France

- Synth. Korund Rubin

- Synth. Korund Saphir

- Synth. Spinell aquamarinfarben

- Synth. Spinell blau

- Synth. Spinell Chrysolith

- Synth. Spinell Erinit

- Synth. Spinell turmalinfarben

- Synth. Spinell weiß

- Tagua

- Tansanit

- Topas

- Trommelsteine

- Tsavorit

- Turmalin

- Türkis

- Yag

- Zirkonia (künstlicher Stein)

- Zitrin

- Zwischenteile

- Verpacken, Aufbewahren

- Etikettieren, Auszeichnen

- Etuis, Verpacken

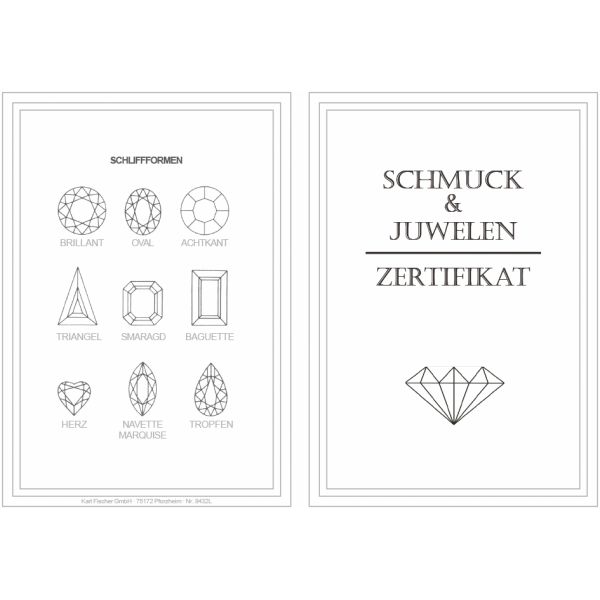

- Gutscheine, Zertifikate

- Lagerung, Aufbewahrung

- Spezialitäten

- 3D-Drucker & Zubehör

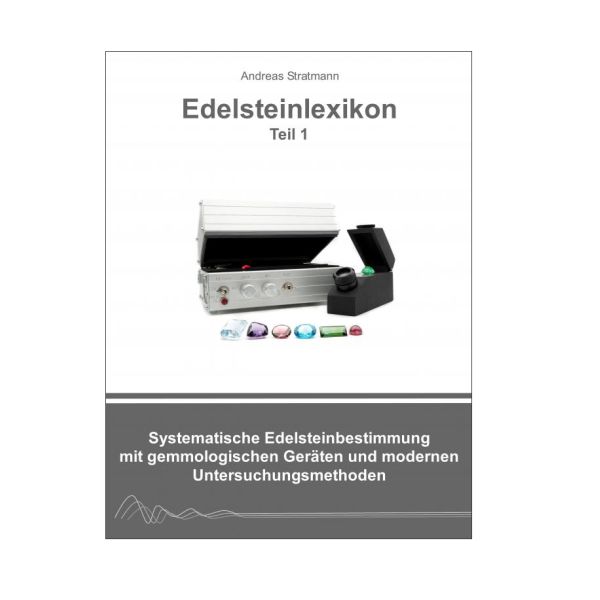

- Bücher, Video, Software

- Digitales Fotostudio

- Goldschmiede-Miniaturen

- Ketten stricken

- Kupfer treiben

- Laserschweißen

- Materialanalyse